I see. It's mostly the acquiring..

I have the same (ish) usb a4 lightpad, and I think it works well. No noticable 'noise' from it.

I did read up on using flats with my asi 1600mm-c and found some things that was true for these dedicated CMOS cameras.

Most of my calibrating was baseed on how you would do with a dedicated CCD, so somethings were needed to change.

First problem I had was Using Dark, Biases and Flats. For the noise of the CMOS chips it is more valuable to do Dark, DarkFlats, and Flats.

This is partly becaus the biases has to short exposuree lenght and causes some random / varying noise.

Because of this it is recomended to do flats with a exposure length of 0.2 seconds or longer, to avoid the varying bias noise, and instead of biases use DarkFlats to calibrate the flats.

So my process no is Lights, Darks, Flats, DarkFlats all at same gain, offset, focus and teemperature

Darks: same exposure length as Lights (but covered)

Flats: 0.2 second exposure length or longer. (I use 0.2s with the dimmable a4 led pad at lowest setting). You use the same focus as when the scope images the sky, so any light source at the devshield should be seriously out of focus, and a even field.

Dark Flats: same as flats, only covered.

In Siri (from googeling, I use PixInsight), you can stack the Flats as Lights and the Dark Flats as Darks. This gives you a MasterFlat

Then stack the Lights with all the darks and the master flat. (This would be the same as calibrating all the Lights with a [Dark Flat calibrated] master Flat and a master Dark in PixInsight), before registering and stacking the Lights.

Looks like it's going to happen!!! Starship sn8 launch!

www.youtube.com/watch?v=Hb59U01YybA

Read More...

Hi Dean.

Can I ask where your struggles in capturing flats are?

Lighting

Settings (gain, exposures)

Calibrating / stacking

Using

Read More...

Clouds as far as I can see, so I'll process some data I have. (From Nov 26-27th)

Celestron AVX, SW Equinox 80 PRO APO and asi 1600mm-cool @Unity, and -25C.

28x 300s subs

150x DarkFlats

50x Flats

25x Darks

Also on my website

observatory17b.com

and on SGL

stargazerslounge.com/gallery/album/4302-observatory-17b/

Hope you like ![]()

Read More...

Just wanted to update my findings here.

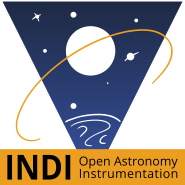

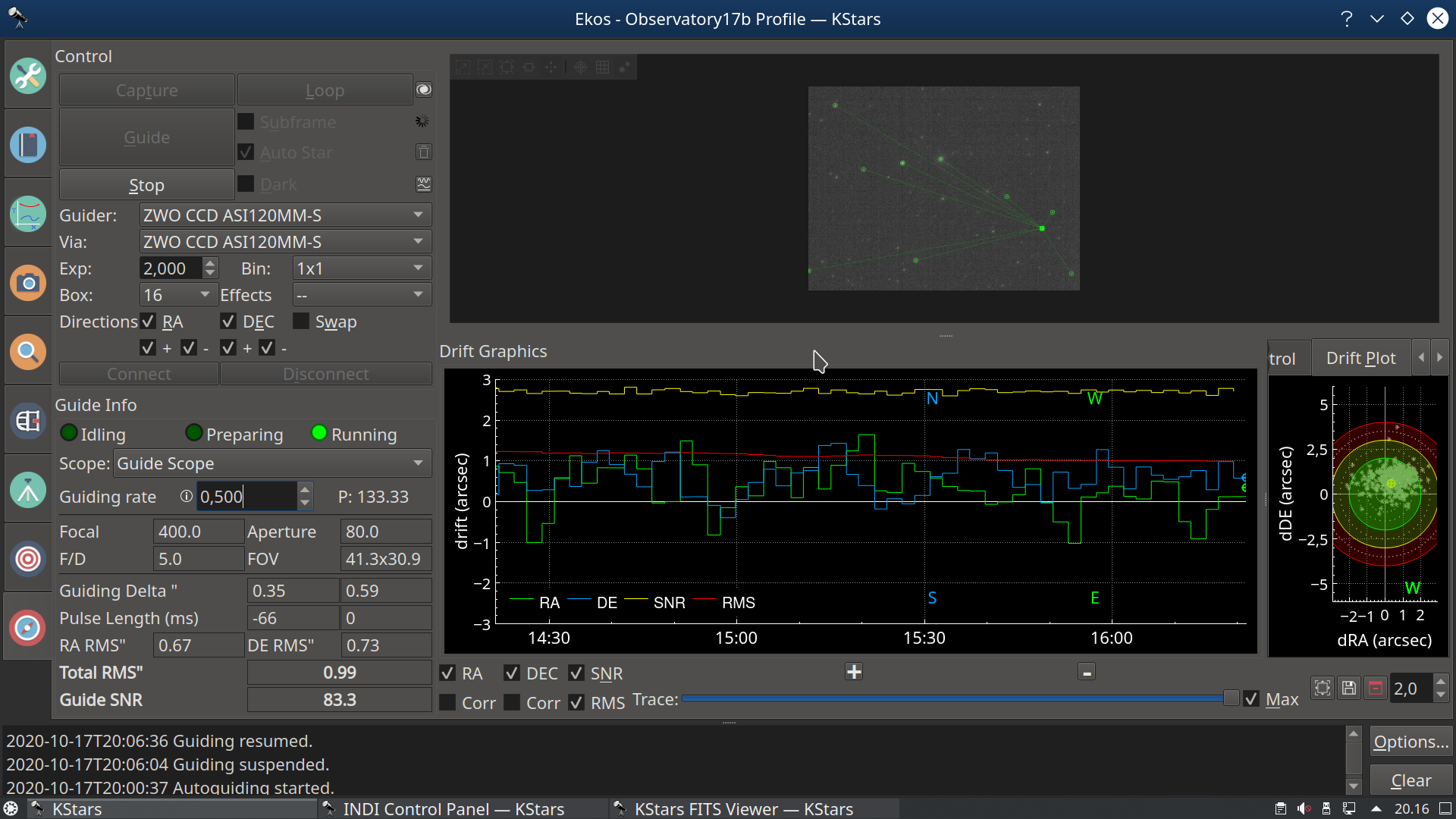

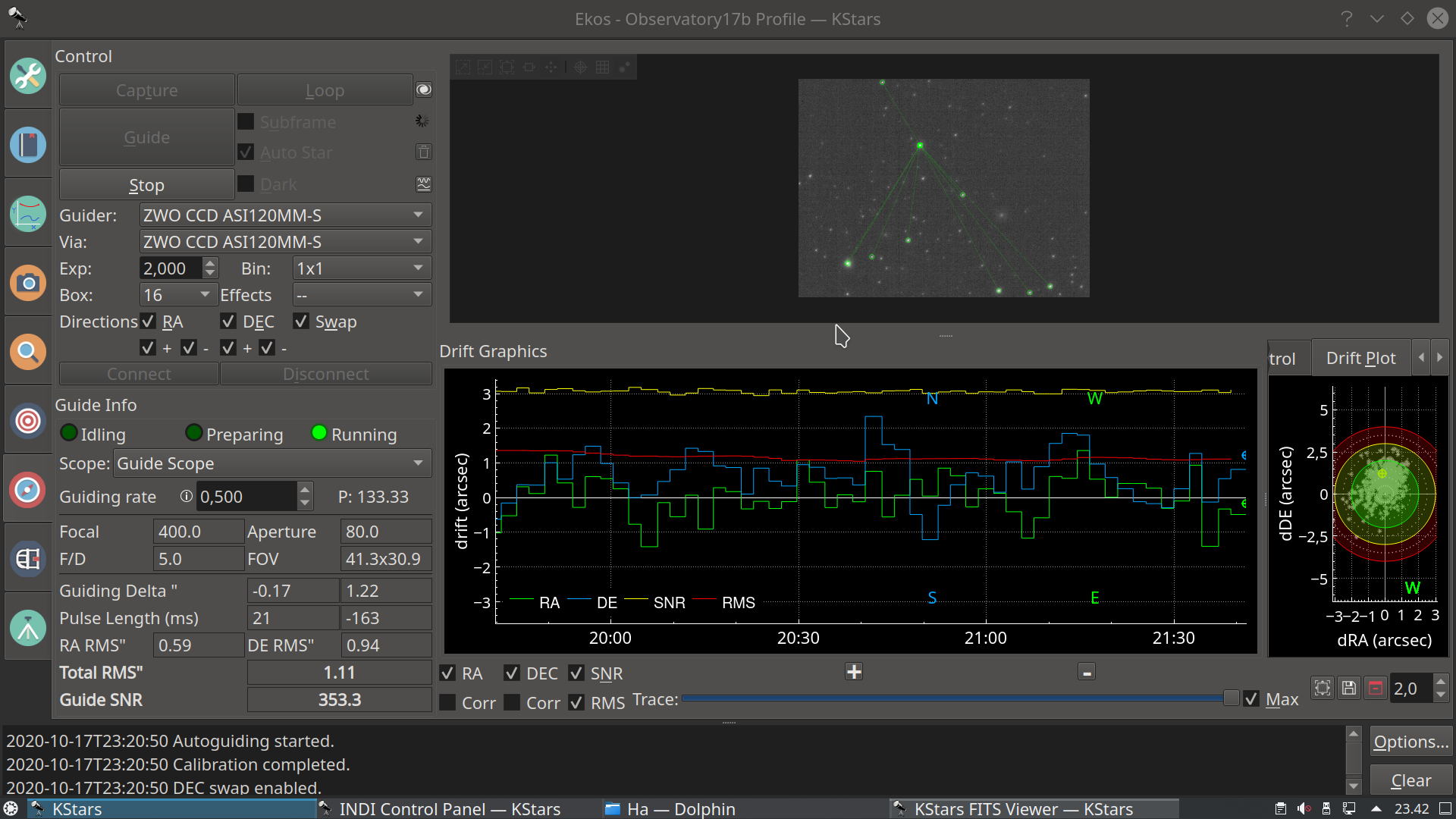

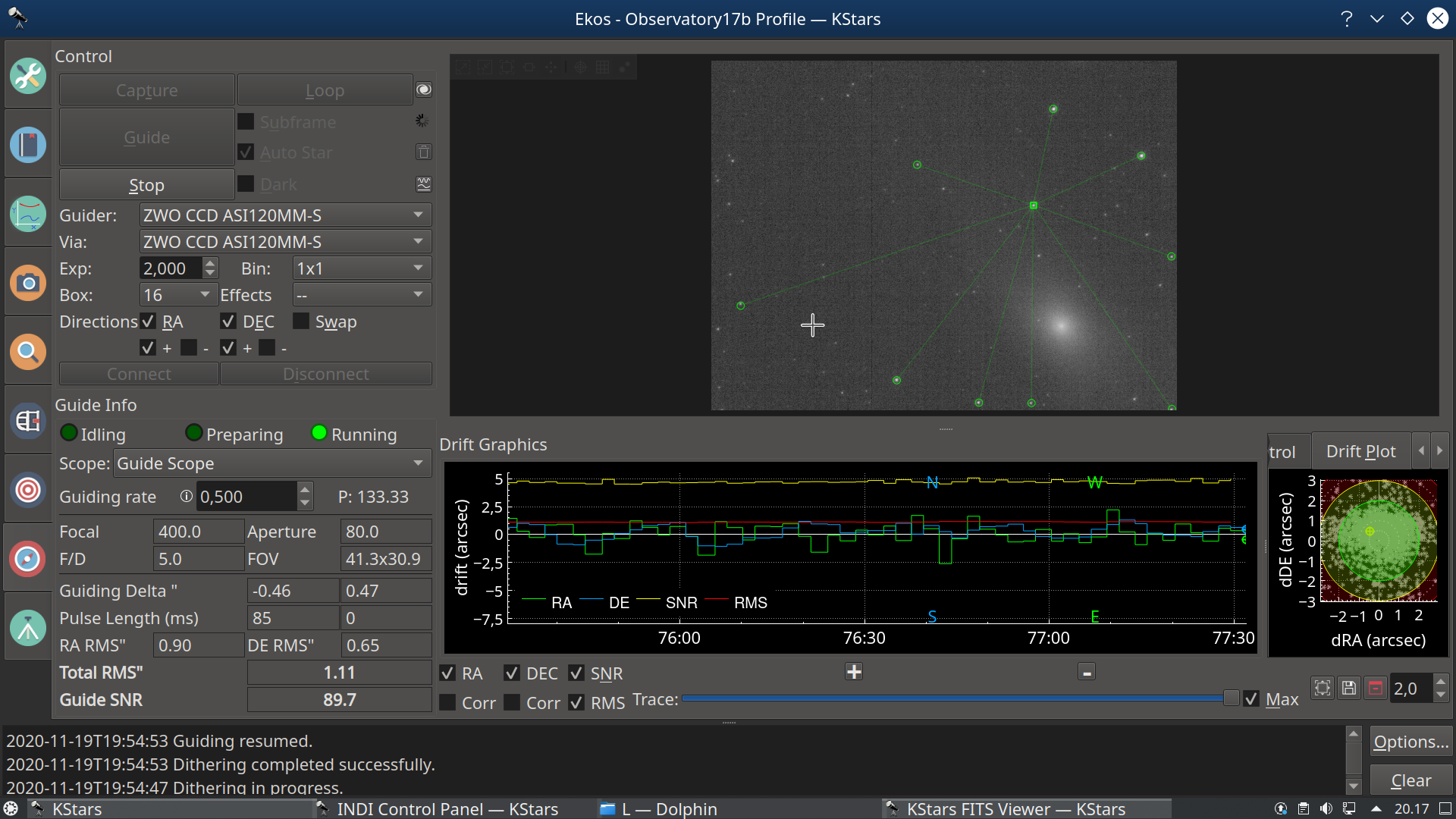

i have been guiding with my new asi 120mm-s (usb3) togheter with my asi 1600mm-c imaging cam. It's just a great mix! Drivers is working great, I have no bugs that can bodge a imaging session now, so that's great.

I hav been using SEP Multistar, sometimes binning 2x. Also with my East heavy balancing mod, AND I went for the 2 second exposure as mentioned previous.

This year I was able to guide at the Elephant's trunk nebula when it past the worst place for the scope to balance (the zenith) with good result.

I also had some guiding sessions with both RA RMS and DA RMS < 1 trough-out the session. Not as great as Stephane's first images in this thread (RA and DA RMS < 0.5!), but still very nice ![]() At the moment every clear sky night is imaging night, so hope to ceep up the pace!

At the moment every clear sky night is imaging night, so hope to ceep up the pace!

Read More...

Hi Jasem, and thanks ![]()

Last time I tried the streaming in INDI was ~ two months ago, not sure if I was on 1.8.7 then, or when 1.8.7 was out?

When I tried it then, everything seamed to work. All the controlls, and streaming preview. However when I opened the file in ser player it was just a lot of noise. (It did roughly show the outline of the moon, but no usable image).

I can test it again next time I get some clear skies, and the moon is there. Longtime weather only shows rain, so might be a while.

Read More...

Full mon from Dec 1th 2020 in LRGB

For this integration I collected a total of 10.000 subs in the .ser format. At Unity gain and -25c i shoot 2.000 subs for LRGB each. I then shoot 2.000 L with a gain of 100, for a HDR L channel. All RGB subs was at 2ms exposure, and all L channel was at 1ms.

Each .ser file was stacked in Autostackert!, then aligned using the FFTRRegistration in PixInsight.

The L channels was combined with HDRComposision, then some curves and unsharp mask. RGB channels was combined, saturated and added to the L channel with pixel math.

I then upscaled the image by 2x.

Scope Equinox 80 PRO APO

ZWO Asi 1600mm-c @-25c

ZWO LRGB filters

Need to get a 2x barlow for these full moon nights ![]()

Hope you like, and Clear skies!

Read More...