Dear Wolfgang,

Thanks in advance for your help!

It's a long topic (though not thát bad), the main part is in page 2 and 3, it's chronological, so makes sense to read up from there. Otherwise I'll just repeat myself and the topic gets even longer.

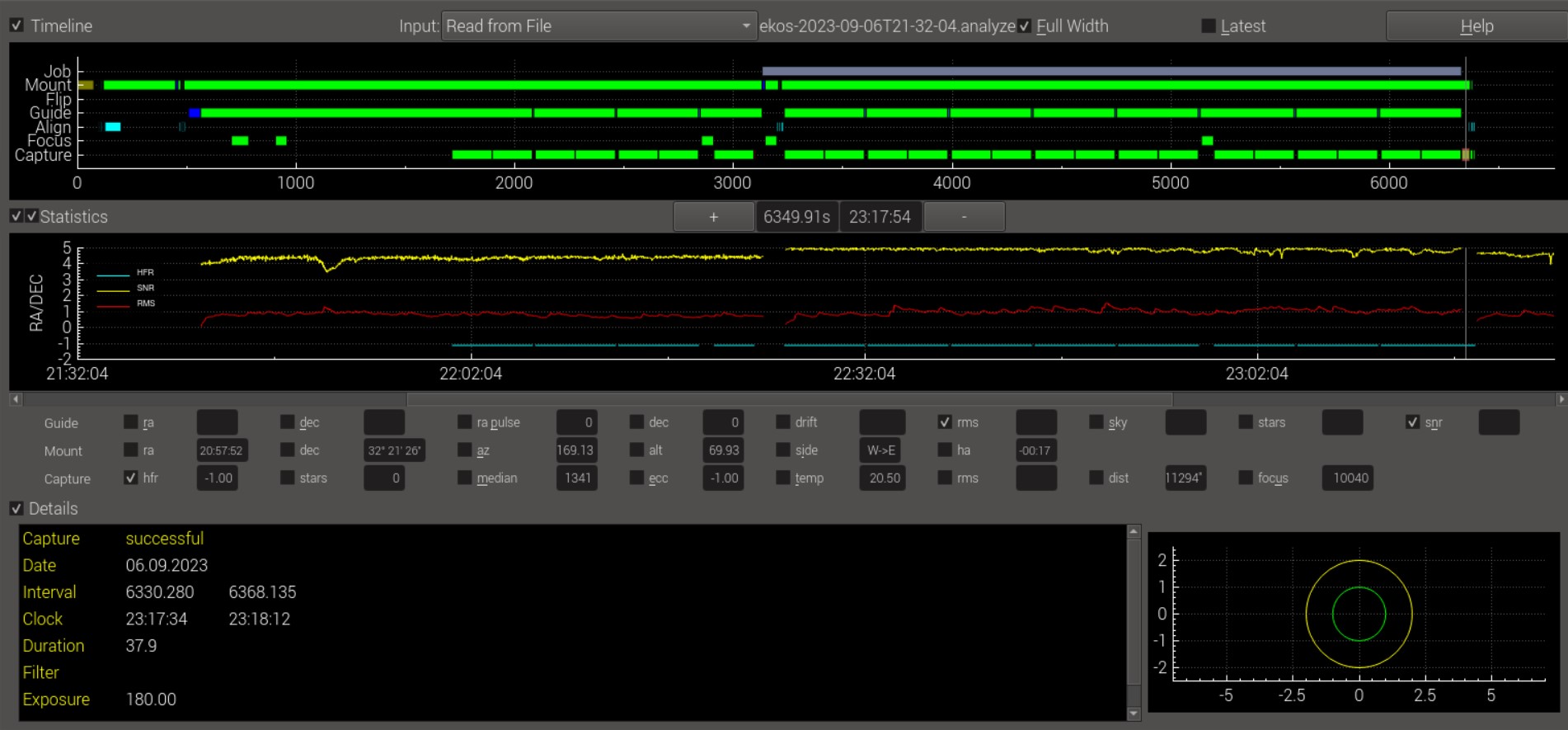

I've encountered the fail a few times now and I have to manually intervene / restart the scheduler if I want to keep it going, otherwise it gets stuck after one, and maybe two jobs (of four).

Again last light this happened:

Analyze tab screenshot: drive.google.com/file/d/1sct3zS5m1NktAh1.../view?usp=drive_link

Log: drive.google.com/file/d/1uqIt3ncFyaXQMkX.../view?usp=drive_link

In this instance, two jobs of 20 lights each were executed, but it failed to continue (there was plenty of 'night' left to continue though!) The jobs currently count 40, 41, 40 and 40 lights (failed at the last 40-th light).

Cheers,

Bart

Read More...

Sure Hy! It was from this session:

It later occurred again, however there are no logs. apparently logging was not enabled 'by default' I'll check next next sessions and make sure it's logging.

Read More...

Yes,

Here the are:

drive.google.com/file/d/1esVKadDDPfeHZBh.../view?usp=drive_link

And for good measure, the scheduler file:

drive.google.com/file/d/1W8igeXwrIX2ZDeq.../view?usp=drive_link

Thanks a lot and hopefully this helps make EKOS better! ![]()

One thing I've did is edit the individual jobs to use a different sequence, as I wanted to use different length lights than when i created the mosaic.

I can't imagine this should matter, but alas here you know.

Cheers,

Bart

Read More...

That looks good!

Now I wonder if another night proceeding with this schedule / job group it would also 'just keep going'.

For me, the issue occured recently again, twice in a night.

I have the logs, but would any dev still like to help out please? ![]()

Read More...

That's a good idea. What I do usually is to start default with a connection to an external 4G hotspot dongle. If that's unavailable, it's own hotspot is created. Feom there, I can connect and select any other available network.

My home wifi doesn't reach the garden that well, so I just plug in an ethernet cable.That's -much better- in any case. Using a flat Cat 5e cable, it fits through the doorsil and the door, no problem.

Cheers!

Read More...

Essentially he wants us to make sure that each job in that schedule has 'repeat until terminated' checked.

(And yes, of course they are)

My hunch is that it has to do with some condition where the 'imager' tab wants to keep going to finish the x images in the sequencer, and at the same time, the scheduler (greedy?) wants to stop that job in order to keep the number of images of the (four) jobs roughly equally fast growing.

It happened before only with the first job, the subsequent jobs go on very well. That's likely because the 'number of required images' is equal to the number of images in that sequence.

Cheers!

Read More...

Ok, this is pretty cool, because I think it actually works now.

For hardware I got a basic model 4G LTE USB modem. It accepts a SIM card and is powered by USB. It also creates a hotspot. Very comparable to creating a hotspot on your phone.

I use a prepaid SIM with 2 GB valid for a year (I have no idea how much it will use, but using it 'every now and then', it doesn't need to be too much.

I've installed RealVNC server on the Rpi4 by:

Sudo apt-get update

Sudo apt-get install realvnc-vnc-server

Raspi config: enable vnc

On the RealVNC website you can create an account, in the account details, create a plan that includes the cloud service (I use the free 'lite' plan).

On the Raspberry I've got the connection to the 4G hotspot created and set to high priority (20).

In RealVNC I'm logged in using my account credentials.

On my tablet / computer I also log in with these credentials.

Startup: create the hotspot first by powering the 4G wifi modem.

Then start the raspberry pi

And the device shows up as available in the VNC viewer on my computer / tablet!

Now I can leave my setup really remote and check in now and then. I just like to share this because it may be of use to other 'semi remote operators' here ![]()

Read More...

I recently got my very mobile setup up and running:

It's a William Optics Star71 (5 element flat field apo) with a 294MC pro mounted on a iOptron HEM15 and controlled by stellarmate on a Raspberry pi4.

I made the carbon fiber guidescope myself (it's -very- lightweight!)

And also the focuser & controller. (Direct drive, usb powered)

I have two filters with this to choose from: a Antlia ALP-T duo narrowband and a IDAS LPS filter for RGB imaging.

I use a powertank out in this field.

Read More...

Hello, because my setup is placed in the field outside the village I live in and me returning home once it's running, I can't directly access it.

Though sometimes it doesn't behave as expected, and needs some manual intervention:

indilib.org/forum/ekos/13719-how-to-repe...lanner.html?start=12

Now I've bought a 4G USB dongle (Mobile wifi) and a data sim.

To try out if I can create a link with 4G.

According to RealVNC

help.realvnc.com/hc/en-us/articles/36000...cloud-connection-0-3

This should be possible.

Now what I would like to know: Can I just install and use this on a 'vanilla Stellarmate' or do I need to do something alike disabling the current VNC server and / or the hotspot?

If this works, I could now and then check in with the setup from home and fix any issues that arise.

Read More...

No, I haven't.

Yesterday I just started it, checked if focus and guiding worked and left it by itself in the field.

Read More...

And for good measure the .esl scheduler file.

Read More...

Tonight the hiccup happened again. I've enabled logging as you requested (verbose and all).

Each job has a sequence with 20 lights.

Starting conditions of the mosaic panels 1 to 4: 40, 24, 20, 20 lights respectively.

Result: 40, 41, 20, 20 lights.

What is strange: 41 lights in the second panel (starting at 24) not 40, not 44 (24+20)...

Please help me out, this is frustrating to say the least. (us Dutch people don't have the luxury of many clear nights ![]() ).

).

Picture of the analysis tab:

Log, excerpt from the last actual light recieved (23:17:32) onward:

Read More...

There was no logging active during that run, however tonight it's active: verbose, file etc.

The rest of the jobs ran smoothly, by the eay, so I suspect the hiccup from before was an edge case.

We'll see soon ![]()

For the rest I'm really pleased by how stable everything runs now, even on the Rpi4.

Read More...

Basic Information

-

Gender

Male -

Birthdate

19. 09. 1984 -

About me

Having fun with astrophotography.

Contact Information

-

City / Town

Leiden -

Country

Netherlands